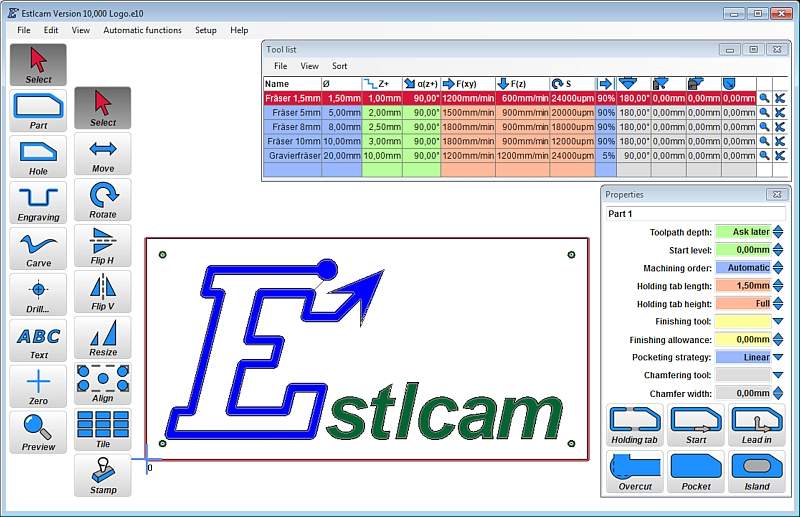

Mar 25, 2018 - GRZ Software makes CNC software for non-machinists. You can try our software for free for 30 days- no limitations! Home » Graphic. CAM (Computer Aided Manufacturing) software converts your CAD drawings into G-code, which is the programming language that the CNC control software understands. The CNC control software then reads the G-code and turns it into motion to drive your machine.

I have been using KCam on a little home built CNC sence 2002. I started with Ver3 and moved up to Ver4.

PSIKOLOGI PERKEMBANGAN page 1 / 1 Powered by TCPDF (www.tcpdf.org). 'Psikologi perkembangan: suatu pendekatan sepanjang rentang kehidupan / Elizabeth B. Buku psikologi perkembangan hurlock pdf files. Perpustakaan Digital Universitas Negeri Malang Koleksi Buku Koleksi Buku 2000 Hurlock, Elizabeth B. Hurlock; alih bahasa Istiwidayanti: Hurlock, Elizabeth B.: 2000: 155.4 HUR p: Jakarta: Erlangga:4: 1. Hurlock; alih bahasa Istiwidayanti '2000 Judul Penulis Tahun Label Penerbit Tersedia Subyek: Psikologi perkembangan: suatu pendekatan sepanjang rentang kehidupan / Elizabeth B.

I run it on an XP computer. Course its has a 2 gig processer in it and it works fine. I really like KCam. Newest Ver Changes per KCam: '*** Version 4.0.16 *** Added Speed Overide Throttle for MaxStepper(Does not work in Parallel Port mode) made small changes in parallel mode Get Timing Constant function. Added Keyboard Jog quick speed adjust (Feed Rate Toggle) with settings at 1/1(normal), 1/2, and 1/10 speed.' I would assume that would make it run smoother.

I have downloaded it but have not tried it yet. I ran TurboCNC 4 on my other home built and had all sorts of move problems. Dropped back to ver 3.1 and it worked fine. But very 'DOS'. I like the windows gui that KCam has. It is simple and clean.

Hey all, I have found Kcam to be the easiest and most user friendly program to get started with. There are definately things to do to optimize the system, but as a previous post says this is more a Windows thing than any Kcam problem. I like the fact that a 4th axis has now also been added as well, and that you get a nice little plot window, and you can also edit the code directly in the program. I think the most important thing is to spend time optimizing the hardware. Eg: I have a stand alone computer purely for CNC, and have removed all unneccessary programs, optimizing the machine (eg: correct power supplies and ratings for motors etc), then minimizing various parts of KCam, plot update etc, and correct setting in the table setup. All simple stuff I know but I wonder how many people have given up on programs, not because of the program itself but ignorance!

Just my 2 cents, now where is my change????? I have kcam4.0.16.can anyone tell me if this kcam software can support windows XP or not???thaNK YOU.yes I run kcam in the office on windos xp I draw with acad dxf to kcam then save the g cods to a memory stick and transfer it to the work shop on to a windos 98 166 processor the computer is 15 years old and with my home built cnc it cuts about 1m 1 minute hers sum projects as for the accuracy I draw a circle 20mm dxf ot kcam set up the tool offset to 1.5 for a 3mm cuter and the set the steps until it cut a nice fit kitsewaviation.com.

Have you done a system timing from the setup menu you must set it so you have 0 freed rate errors if not it may be your step settings 1/8 1/4 1/2I was trying to get time constant, but I always have some feed rate errors. They were close to 0, but newer 'pure zero'.

I use UHU servo controller, it is built for 3 axis, but now I have only one connected to my machine ( Z - axis). I´m trying to run this simple G-code (just to move up and down): G00 Z0 G00 Z40 G01 Z35 G00 Z0 G00 Z50 G00 Z0 For G01 I have speed 40mm/min, for G00 I should have 200mm/min. Interesting is, that only movement in the last step (G00 Z0) is with proper speed, all other movements looks like G01. My OS is Windows 2000.

Archive

- Vocal Rider Vst Cracked Magazine

- Descargar El Lunatico Y Su Hermana Libertad Pdfescape

- Colorimpact 4 1 2 Setup Key For Media

- Contoh Proposal Seminar Kewirausahaan Pdf Merger

- How To Download Mastin Labs Fuji Pro Pack

- Vw T5 Transporter Bedienungsanleitung Pdf Free

- Jetbrains Phpstorm Keygen

- Prince Paul A Prince Among Thieves Rar Download

- Folder Lock For Windows 8 64 Bit With Crack Kickass Torrent

- Shipconstructor 2013 Dodge

- Modbus Serial Master Jamod 115

- Chord Gitar Lagu Indonesia Terbaru Pdf Editor